From Wheel Cover Wire Ring,Custom Round Wire Rings, Industrial Gauges to Jigs & Fixtures, Sukriti Design Engineer & Consultant design & engineers all kinds of tools for several manufacturing firms.

Mr. Ravinder Kumar founded Sukriti Design Engineer & Consultant in the year 2010. At that time, the company started operating in a small tool room and fabricated wire rings, to be fitted in wheel covers of cars. Based in Gurgaon, Haryana (India), the Manufacturer and Supplier steadily grew in terms of its production capacity, infrastructure and sales. Due to its latest production techniques and maintaining quality standards, the company received ISO 9001:2015 Certificate. And, due to its ethical business practices, it also started getting orders from international buyers. With the dedication and hardwork of our employees, we have been able to make a turnover of 5 CR.

The products it manufactures include Wheel Cover Wire Ring, Wire Components, Medium Wheel Ring, Custom Round Wire Rings, Steel Wire Ring and more. To cater to the unique demands of clients, we also provide customization solution. We make products according to the specifications provided by them. Whether they want to change the grade of material, design, style, capacity, size, shape, finish or color; we can incorporate the changes in the standard range.

Make your

enquiry now !

Talk to us! we will be glad to assist

you.

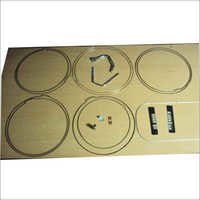

Product Gallery

-

Custom Wheel Wire Rings -

Wire Ring unit -

Wheel Cover Wire Ring -

Wire Wheel Rings -

Round Wheel Wire Rings -

Wheel Cover Wire Ring -

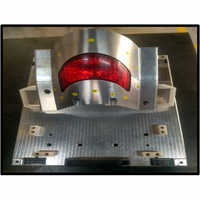

Industrial Lighting Fixture -

Industrial Light Fixture -

Light Testing Fixture -

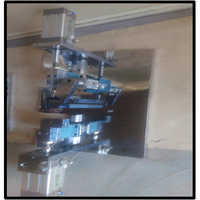

Mahindra Welding Fixture -

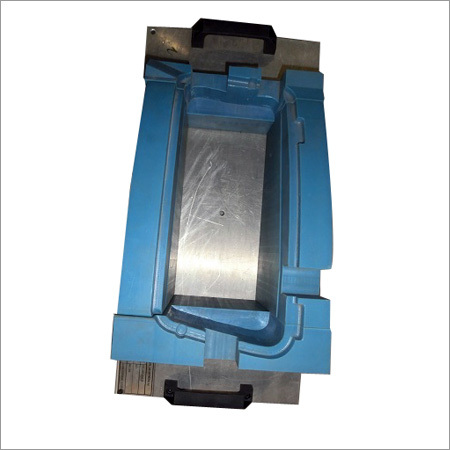

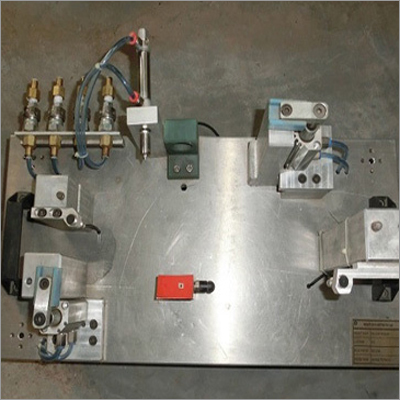

Industrial Jigs Fixture -

Ashok Leyland Lever Rod Welding Fixture -

Industrial Gauge -

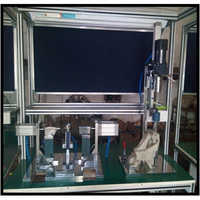

Production Line -

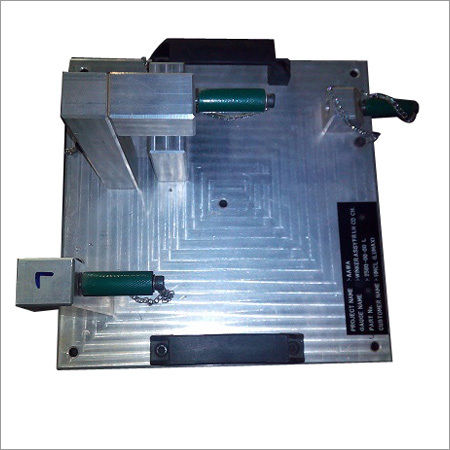

Panel Checker -

Panel Checker Machine -

Sheet Metal Component -

Sheet Metal Component -

Engine Mounting Bracket -

Gear Knob Fitment Machine -

Special Purpose Machine -

Bush Pressing In Gear Shifter -

Tail Lamp Assembly Line -

Lens Pressing Station -

Gear Pressing Machine -

Assembly part

Production Facility

All the products when produced are measured to ensure its proper dimensions. For checking the minute details and specifications of these products, our engineers use following equipment:

Quality

From cutting and coiling to wire, straightening and cutting to bending and welding, all tasks of converting the metal into wire ring are executed in-house by engineers and technicians in our two production plants. The manufacturing unit is installed with all requisite machinery to aid the experts perform such tasks and these machinery and equipment, include the following:

- Automatic Wire Bending & Cutting Machine

- Wire Straightener- 0.3 to 6 mm

- Power Press- 5T to 300T

- Resistance Welding (Automatic) Machines (3 MIG, 3 Electric Arc, and 1 TIG)

- Projection Welding Machine

- 2 Traub

- 2 Cutting Coiling Machines Developed in House

- 1 Coiling Machine Developed In House

- 2 Straightner & Cutter

In the tool room, we have installed machinery, like:

- 3 DRO Milling Machines M1TR (Pacmill)

- 2 Surface Grinders (Guru Arjun)

- 1 Lathe (Everest)

- Drilling Machine (Everest)

- 1 3-Axis Vertical Machining Centre

- 1 6D Wire Shaping CNC Machine

- 1 CNC Turning Centre

- 1 3-Axis Pipe Bending Machine

We also use other machines such as:

- 2 Compressors

- 1 Diesel Generator Set

- 1 Booster

- 1 Hand Grinder

- 1 Hand Dry Cutter

All the products when produced are measured to ensure its proper dimensions. For checking the minute details and specifications of these products, our engineers use following equipment:

- Height Gauge (Dial/Digimatic) 300 mm (Mitutoyo)

- Micrometer: 0-25 mm, 25-50 mm (Mitutoyo)

- Surface Plate: 1000mm*1500mm

- Vernier Calipers (Dial/Digimatic): 300 mm (Mitutoyo)

- Radius Gauge: 0-25mm

- Push Pull Gauge: 0-100 kgf

We also manufacture tools, like:

- Press tools

- Jigs & Fixtures

- Special Purpose Machine

- Assembly Line Automation

- Industrial Gauges

Quality

As an ISO 9001:2015 certified company, it follows all the regulations during manufacturing our range. Thus, the clients can be assured that the products are developed in lines with the internationally accepted standards. Our personnel check few of the products produced in the batch and only when the sample passes these tests, the complete batch is approved. The jigs and fixtures created undergo light testing LH and leakage testing RH. We also follow QCD fundamental in which Q stands for Quality; C stands for Competitive Priced Products; and D stands for Prompt Delivery.

Major Clients

We have served the jigs, fixtures, wire rings and other tool needs of many companies. We have listed the names of few of the loyal clients below:

- Lumax industries

- Lumax mannoh

- Neolite lightings pvt. Ltd.

- Alpha maier pvt.ltd.

- Vbros auto pvt. Ltd.

- Enco engineers combine pvt. Ltd.

- Mindarika

- Minda

- Rinder

- Nippon

- Polyplastics

Important Practices Followed:

- FIFO First In First Out

- Route Card System To maintain transparency.

- Kaizen

- Cause and Effect Diagram

- Change Management Recorded

- Abnormality Handling Recorded

- Regular Upgradation of Staff

- Regular Maintenance of Machines and Fixtures

|

Sukriti Design Engineer & Consultant

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |